Current ConnectedDredge Subscribers CLICK HERE to log-in and access your data.

Revolutionize your aggregate dredging operations with ConnectedDredge, a comprehensive dredging software and hardware solution from Measutronics. With this one-of-a-kind system, dredge superintendents can overcome challenges like data silos, inefficient delayed monitoring, and compliance complexities. Leverage real-time data and advanced georeferenced analytics to improve efficiency and expedite decision-making while remotely monitoring and managing your dredging operations.

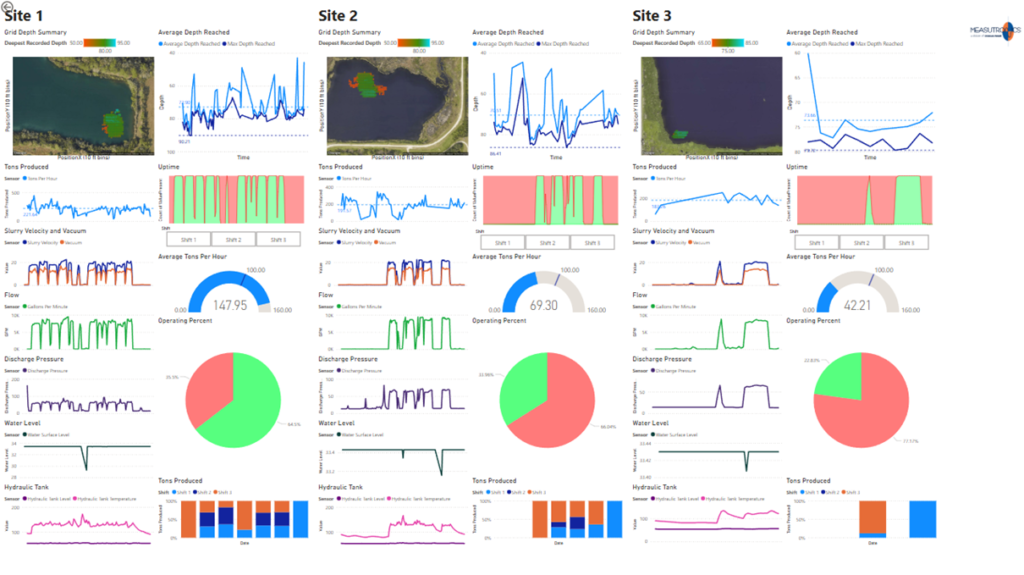

Representative Data Display

Real-Time Data and Georeferenced Insights

ConnectedDredge helps you know the locations and depths your dredges are achieving, all correlated with traditional plant performance metrics. The system uses georeferencing to tie performance metrics to time and geographical position — identifying where and when production rates are being achieved or falling behind. This real time data allows managers to make informed decisions more quickly with regard to expected production or correcting deficiencies for improved output.

Our purpose-built software is tightly integrated with the Trimble Marine Construction (TMC) cutter suction dredging (CSD) guidance system. TMC allows the dredge operator to monitor the position and depth of the cutterhead in real time using continually updated 3D visualizations with both plan and profile views. With ConnectedDredge, traditional plant operating metrics are automatically timestamped and geolocated, so remote managers know when and where dredging takes place.

The ConnectedDredge dashboard can track and log performance metrics like:

- Slurry velocity

- Vacuum

- Hydraulic tank temperature

- Gallons per minute flow

- Discharge pressure

- Uptime and downtime

- Tons per hour

- Production rates per site/dredge/shift/operator

Purpose-Built for Dredging Professionals

Our dredge performance analysis software is purpose-built. TMC provides operators with real-time feedback as they dig while ConnectedDredge summarizes operations on a continual basis, made available for management’s remote viewing. Nearly two years in the making, we have worked with dredge manufacturers, mine managers, and dredge operators in creating a unique blend of typical machine telematics coupled with geospatial-based performance metrics.

One of the features dredge managers wanted that we incorporated into ConnectedDredge is the option to break down production by site, by dredge, and by shift. ConnectedDredge can break down data based on a user-defined time frame. See how many tons each shift produced today, this week, or this month. You can adjust the time frame and displays automatically to reflect the new time period and review real-time data. The shift breakdown makes it easy to identify differences between shifts and correlate these differences to procedural differences. ConnectedDredge will enable you to train new operators in short order, making inexperienced operators proficient more quickly.

Identify and Resolve Issues Faster

Our dredge monitoring software identifies problems as they happen for fast remediation. ConnectedDredge can alert you to equipment operating outside designated parameters, outages, and sensor failures to minimize downtime. Designated members of your team, as well as our support staff, will receive an alert if a sensor fails. Troubleshooting begins immediately.

Improve Operator Training and Efficiency

ConnectedDredge displays trending data, allowing managers to identify procedures that need corrective action so they can train their operators on correct operations. Our technology also increases efficiency by enabling remote managers to access the most current production data and trends.

Compare the efficiency rates between your operators to identify training opportunities for your team. With your operators following procedures and working efficiently, you can get the desired results without guesswork or costly rework.

Remote Monitoring and USACE DQM Compliance

Access data anytime, anywhere with ConnectedDredge’s remote monitoring capabilities. With an internet connection, your site supervisors and plant managers can perform remote dredge monitoring to assess operations. Cellular- or satellite-based connectivity facilitates both data transfer and remote support as well.

Measutronics is a United States Army Corps of Engineers (USACE) authorized Dredging Quality Management (DQM) provider, and ConnectedDredge is compliant with USACE DQM requirements.

Data-Driven Insights for Better Decision-Making

As a dredge data management platform, ConnectedDredge provides data-backed insights into your dredging operations, so site supervisors can make timely, strategic decisions to optimize operations. Take advantage of immediate results for your management purposes without waiting for a bathymetric survey, when and if available.

With ConnectedDredge, managers can identify areas with remaining material and delineate them for the operators in TMC before moving the dredge to new areas, thus preventing rework. ConnectedDredge will also aid in identifying operational issues, such as downtime or slowed progress, allowing managers to adjust procedures or production estimates accordingly. Continuous data logging allows you to review historical data to generate production reports.

Regional mine managers who need to track more than one dredge can view the same metrics for each dredge and site side-by-side. They can compare the performance of the dredges to evaluate efficiency, ensure normal operations, identify problems, and make adjustments as necessary.

Maintenance and Troubleshooting

The data metrics from ConnectedDredge support your maintenance and troubleshooting efforts. Data metrics can:

- Provide insight into machine wear and tear and maintenance requirements.

- Track typical plant and machine telemetrics like run time, temperatures, and pressures.

- Track how often a dredge experiences downtime.

Salient Features of Our Dredging Technology

ConnectedDredge offers numerous features for productive and strategic dredging, including:

- An integrated system: ConnectedDredge’s integration of TMC capabilities tie performance metrics to geospatial and time data.

- Production data metrics: Our dredge data management software automatically logs and archives production data metrics for historic review.

- Timeline slider bars: Timeline slider bars change the hour, day, week, or month for the data. Each associated visual, like maps and graphs, will change automatically to reflect the time period chosen.

- Alarms: The alarm feature provides email alerts to dredge superintendents, site managers, and key decision-makers when anomalies occur. When data falls outside defined thresholds or sensors fail, you can act quickly to correct the issue before it becomes a larger problem.

- Cloud-based data storage: ConnectedDredge stores data points in a cloud storage environment, which you can access anywhere you have an internet connection.

- Customized reports available: Use your dredging data to review performance and identify production improvement opportunities.

Pricing Details for ConnectedDredge

Provide us with your application details, and Measutronics can give you a quote for your ConnectedDredge system.

Request a Demo or Quote for Our Dredge Management Software Today

Measutronics is your trusted expert for dredge guidance technology. Contact Measutronics today to request a demo for ConnectedDredge or to get a personalized quote for your dredge operations platform.